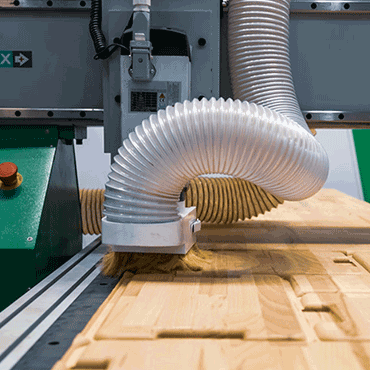

Woodworking

Home / Application

Dust Collector Application

Grain and Food

Welding and Cutting

Sandblasting and Spraying

Coal and Biomass Boiler

Cement and Lime

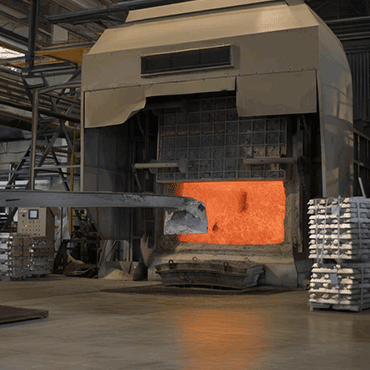

Steel Prodction and Casting

Copper and Aluminium Smelting

Please send your message to us

If you would like to form a partnership with Chengtai, please fill out our Become a Partner form. Our dealership management team will contact you to discuss further cooperation one-on-one.

- *Tel

- *Title

- *Content